- [email protected]

- +90 212 470 62 02

Pelet Makinası İmalatı

Distributer

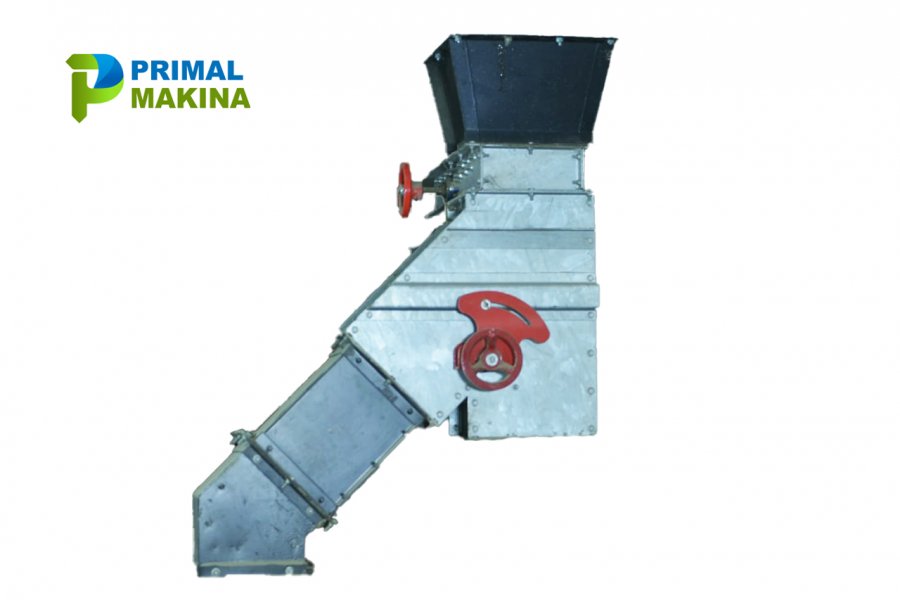

Distributor: Optimizing Material Flow in Bulk Handling Systems

A distributor is a vital piece of equipment in material handling systems, designed to effectively route bulk materials like grains, seeds, and other granular products to different storage locations or processing lines. In operations where efficiency and precision are critical, the distributor plays an essential role in directing materials with minimal spillage or waste. Primal Makina’s distributors are engineered to deliver reliable performance, ensuring smooth and controlled distribution of materials in a wide range of industries.

What is a Distributor?

A distributor is a rotating or fixed device that directs materials from a conveyor, elevator, or similar handling system to multiple discharge points. These discharge points could lead to storage silos, processing equipment, or packaging areas. The primary function of a distributor is to ensure that materials are evenly and efficiently distributed without contamination or loss. It is a crucial element in multi-line systems where different materials need to be allocated to specific locations.

Key Features of Distributors:

- Multiple Discharge Points:

Primal Makina’s distributors are designed to accommodate multiple discharge outlets, allowing materials to be directed to different locations based on operational needs. - Smooth Rotation Mechanism:

Our distributors come with high-quality bearings and smooth rotation mechanisms, ensuring quick and efficient switching between discharge points without jamming or interruption. - Durable Construction:

Made from robust materials such as galvanized steel or stainless steel, Primal Makina’s distributors are built to withstand the rigors of continuous operation, ensuring long-term reliability and performance. - Manual or Automated Control:

Distributors can be operated manually or automated, depending on your system’s requirements. Automated distributors allow for faster and more efficient switching between lines, minimizing labor and downtime. - Customizable Design:

Distributors can be customized to fit your specific material handling needs, whether it's adjusting the number of discharge points or integrating them with existing equipment.

Benefits of Using Distributors:

- Increased Efficiency: Distributors ensure that materials are directed to the right location quickly and efficiently, streamlining operations and reducing downtime.

- Improved Flexibility: With multiple discharge options, distributors allow facilities to handle different materials or processes simultaneously, improving operational flexibility.

- Reduced Material Loss: By providing a controlled pathway for materials, distributors minimize spillage and contamination, ensuring that the maximum amount of product reaches its destination.

- Lower Operational Costs: By automating the distribution of materials, businesses can reduce labor costs and increase overall system efficiency, leading to long-term cost savings.

- Space Optimization: Distributors help organize material flow within a facility, reducing the need for multiple conveyors or equipment, and making the best use of available space.

Applications of Distributors:

- Grain Handling Systems: In grain storage and processing facilities, distributors direct grains such as wheat, corn, and barley to specific silos or processing lines, ensuring that different batches are efficiently separated.

- Feed Mills: Distributors are used to channel different types of feed ingredients to designated mixers, ensuring that the right ingredients reach the correct production lines without contamination.

- Food Processing: In the food industry, distributors help ensure that ingredients are delivered to various stages of production, packaging, or storage without cross-contamination or spillage.

- Bulk Material Handling: In industries like cement, mining, and construction, distributors are used to route raw materials or finished products to different processing or storage areas, ensuring smooth operation in large-scale production environments.

Conclusion:

A distributor is a critical component in any bulk material handling system, ensuring the efficient and accurate flow of materials to multiple destinations. Whether you are in agriculture, food processing, or industrial manufacturing, Primal Makina’s distributors provide the precision and reliability you need to optimize your operations.

For more information on how Primal Makina’s distributors can improve the flow of materials in your facility, contact us today. Our experts are ready to provide customized solutions tailored to your specific needs.

Fiyat Teklifi İste WhatsappFiyat Teklifi Al

Ürünlerimiz ve teknik hizmetlerimiz hakkında tüm sorularınız için aşağıdaki formu doldurun, en kısa sürede size geri döneceğiz.