- [email protected]

- +90 212 470 62 02

Pelet Makinası İmalatı

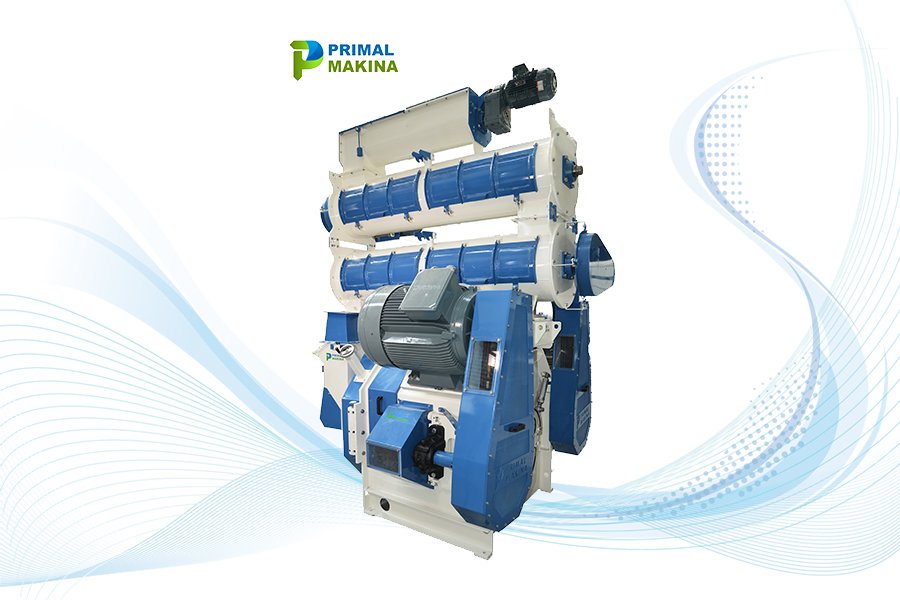

Twin Conditioner

Twin Conditioner: Enhancing Feed Processing Efficiency

The twin conditioner is an advanced piece of equipment commonly used in the feed production process to improve the quality and consistency of animal feed. It plays a crucial role in preparing the feed ingredients before the pelleting process by ensuring optimal conditioning, which improves feed digestibility, palatability, and overall nutritional value.

How the Twin Conditioner Works:

The twin conditioner operates with two interlocking shafts that rotate in opposite directions, equipped with paddles or blades. This design allows for thorough mixing of feed ingredients with steam or water, ensuring even moisture distribution and optimal temperature throughout the material. The result is a properly conditioned feed that is ready for efficient pelleting.

Key Features:

- Enhanced Mixing Efficiency: The twin shaft design ensures thorough and uniform mixing of steam and feed ingredients, resulting in a consistent product. This uniform conditioning is essential for creating high-quality pellets with a durable structure.

- Temperature and Moisture Control: The twin conditioner allows precise control over temperature and moisture levels, which is vital for maintaining the integrity and nutritional content of the feed. Proper conditioning increases starch gelatinization, which improves pellet binding and digestibility.

- Adjustable Retention Time: One of the standout features of the twin conditioner is its ability to adjust retention time. This ensures that the feed material is conditioned long enough to absorb steam and water evenly, leading to a higher-quality end product.

- Durable Construction: Built to withstand the demands of industrial-scale feed production, the twin conditioner is constructed from high-quality, corrosion-resistant materials. This ensures long-term performance and minimal maintenance requirements.

- Flexible Design: The twin conditioner can be customized to handle various feed formulations, making it suitable for producing different types of feed, including poultry, livestock, and aquaculture feed.

Benefits of Using a Twin Conditioner:

- Improved Pellet Quality: Proper conditioning is key to producing durable and homogenous pellets. The twin conditioner helps create pellets with better binding properties, reducing fines and improving feed quality.

- Increased Feed Digestibility: By increasing the gelatinization of starches, the twin conditioner enhances the digestibility of feed, resulting in improved nutrient absorption by animals.

- Energy Efficiency: Well-conditioned feed requires less energy to pellet, leading to lower energy consumption during the pelleting process.

- Consistent Performance: The twin conditioner ensures consistent feed quality, which is essential for maintaining the health and growth of animals.

Applications:

The twin conditioner is used across various sectors in the feed industry, including:

- Poultry Feed: Ensures optimal conditioning for improved pellet quality and digestibility.

- Livestock Feed: Prepares feed ingredients for efficient pelleting, improving feed texture and nutrient availability.

- Aquaculture Feed: Conditions feed ingredients to meet the specific needs of fish and other aquatic species, improving feed performance.

Conclusion:

The twin conditioner is a critical component of modern feed production systems, offering superior conditioning capabilities that lead to better feed quality, improved pellet durability, and enhanced digestibility. With its precise temperature and moisture control, the twin conditioner ensures efficient processing and consistent results.

Investing in a twin conditioner will optimize your feed production, reduce operational costs, and enhance the overall quality of your feed products. Contact Primal Makina today to learn more about how our twin conditioners can transform your feed production process.

Fiyat Teklifi İste WhatsappFiyat Teklifi Al

Ürünlerimiz ve teknik hizmetlerimiz hakkında tüm sorularınız için aşağıdaki formu doldurun, en kısa sürede size geri döneceğiz.